Mari-Ann Meigo Fonseca: 'Gelatex' leather like material - a better alternative for the garment industry

With seven years of experience in the fashion industry, Mari-Ann’s goal with 'Gelatex' is to scale up the production of an eco-friendly leather-like material to replace leather. 'Gelatex' materials are made from waste generated from the meat industry and, contrary to leather tanning, it uses non-toxic processes. The technology developed promises an easily scalable, affordable, and eco-friendly material that can positively contribute to improve the environmental footprint of the fashion industry.

By Alberto Giacometti, Nordregio

According to 'Gelatex', the livestock industry uses up to 60% of the animal for meat, while the rest is often discarded. In Europe alone, 5 million tons of animal waste is incinerated each year. This by-product of the livestock industry is an enormously undervalued resource. Mari-Ann and team have developed a technology to produce nano-fibrous materials from gelatine deriving from animal waste processing. Their flagship product is a leather-like material, which shares similar properties to real leather.

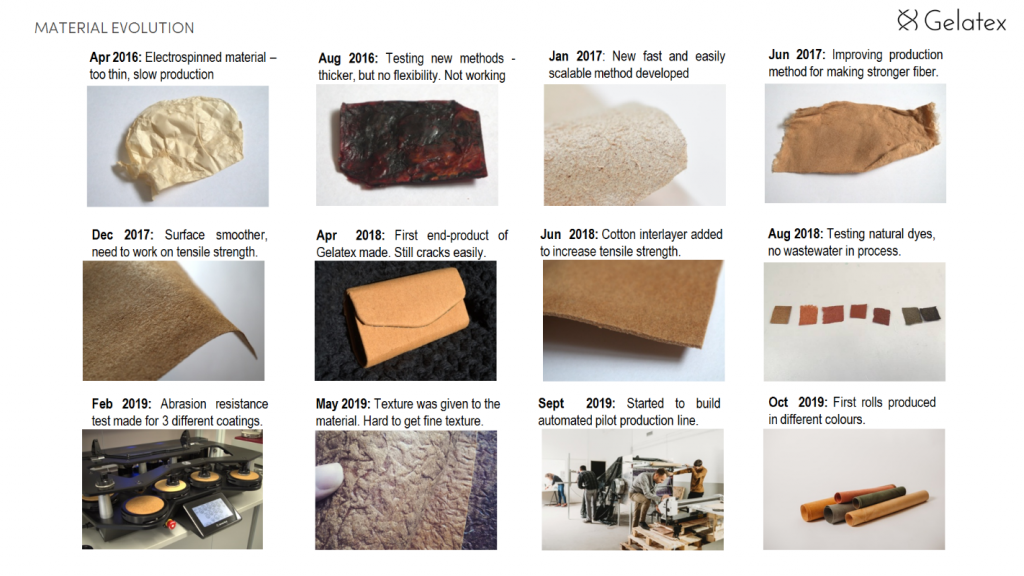

'Gelatex' technology consists of spinning a nano-fibrous mesh from a gelatin-based solution. The resulting mesh is then laminated with cotton and finished with sustainable additives that provide a durable quality and attractive touch.

With this innovation, Mari-Ann and team offer a textile that can be used as a more sustainable alternative to leather in the garment industry and interior design. So far, they have collaborated with Stella Soomlais, a renown Estonian designer to design bags and other accessories made of 'Gelatex' material. Also, in collaboration with NO/AN, a Finnish high-end handbags brand, 'Gelatex' has started to develop the first high-end bag collection using 'Gelatex' material.

Impact & Benefits

There are many benefits of 'Gelatex' material to the environment and human health. Today, there is a vast amount of waste resulting from the livestock industry, most of which is incinerated. 'Gelatex' offers a technology to upcycle that waste, extending its potential use and replacing the need for less sustainable alternatives.

The leather industry utilises highly toxic chemicals in the tanning, which is highly damaging to the health of the industry’s workers. Tanneries also utilise and pollute significant amounts of water. 'Gelatex' material does not require any tanning and dyeing is done in a harmless manner. 'Gelatex' production adds colour pigments before creating the fibres, avoiding the use of toxic chemicals and using 28% less water compared to leather production. Being the tanning and dyeing processes in leather and textile industries extremely polluting, 'Gelatex' comes about as a much more sustainable alternative. Moreover, 'Gelatex' material comes in rolls, with uniform shapes, reducing material waste. It generates job opportunities locally and a reduces potential emissions by replacing the need for meterials shipped overseas.

Journey

Mari-Ann was working as a garment technologist, with technical product design, when her interest in eco-materials and eco-textiles started to develop. “Seeing all the waste that comes from the textile industry was a trigger for me”. At the same time, Mari-Ann got to see and work with alternative products, that served as inspiration to rethink the textile production process.

Mari-Ann registered to an MBA in entrepreneurship and technology management at the University of Tartu where she also joined an ‘eco-innovation club’. “I got interested in writing my thesis about eco-materials and then I found material scientists at the university who were working with gelatine-based materials”, which are made from the waste of the meat industry. Back then, they did not have a clear purpose for what to produce with this technology. They were testing a base-material for cell-growth to be used in the medical sector. But, “because of my background, it made sense to work on a leather-like material”.

“Back in spring 2016, the world had started moving towards veganism and alternatives to animal-based materials, so I was doubting whether it would make sense to go further with this idea”. But as they did more research about it, they figured that there is a huge amount waste resulting from animal industry today, and at the same time, there is an enormous impact on human health for people working in leather tanneries. According to Mari-Ann, “there are ways to produce leather in an eco-friendly way, but they are not scalable and slow to produce”.

“To make an impact you would need something that can be mass-produced, something that car and furniture industries can use”, she adds. Based on this research, Mari-Ann and the material scientists realised that it made much sense to produce a gelatine-based material, which “is organic, chemically similar to leather, affordable, and easy to use as it comes in roles”.

Mari-Ann, in collaboration with the university’s material scientists, registered to a ClimateLaunchpad – one of the world’s biggest competitions for green business ideas offered by EIT Climate-KIC. “You don’t need to have a final product or a prototype, you simply present your idea and they help you develop it”. Their idea was selected among other 10 in Estonia to participate in a support programme, where Mari-Ann received intensive coaching and mentoring. After successfully passing the national competition, the team won the global competition.

“This was a very useful programme - it gave us a lot of knowledge early on”. They were awarded with 10.000 Euro and access to the Climate-KIC ClimateLaunchpad Accelerator, where they are helped to develop their idea into a business.

Additionally, last year, they participated at a TechStars event in Indianapolis, USA, where they received technical and business mentoring as well as non-equity financing support. With that support they are developing the material and searching for collaborations and investors to scale up production.

Challenges

One of the key challenges with 'Gelatex' is that “in some-way we are going against the flow – the vegan trend”, Mari-Ann explains. “So, we don’t know if this is going to be huge or not”, she adds. It depends on the trends. Sometimes the sustainability discussion can be black-and-white. But so long as there is a meat industry, 'Gelatex' product makes sense from an environmental perspective.

It is hard to be 100% sustainable. Mari-Ann thinks “it is good to be open minded – it’s easy to get stuck in your idea – but we have to be adaptive to what is happening in the market – and pragmatic if we are going to sustain our business”.

Next steps

An unexpected turn of events came with the COVID-19 pandemic. Giving the lack of facemasks in the market, 'Gelatex' adapted their technology to produce filtering materials based on a SAN polymer. This “is not a sustainable material, but right now there is an urgent need for facemask to protect human health” explains Mari-Ann. “Still, we are making tests to improve our material and find a better alternative for the environment” she adds.

The focus on developing the leather-like material will continue after overcoming the Covid-19-crisis, while in the meantime, the liquidity received from the facemask production will help them sustain the business. As the temporary turmoil goes on, the team is preparing for fundraising and speed up the growth of 'Gelatex'.

Photos: 'Gelatex' archive.